5 Simple Techniques For Sandblasting

Wiki Article

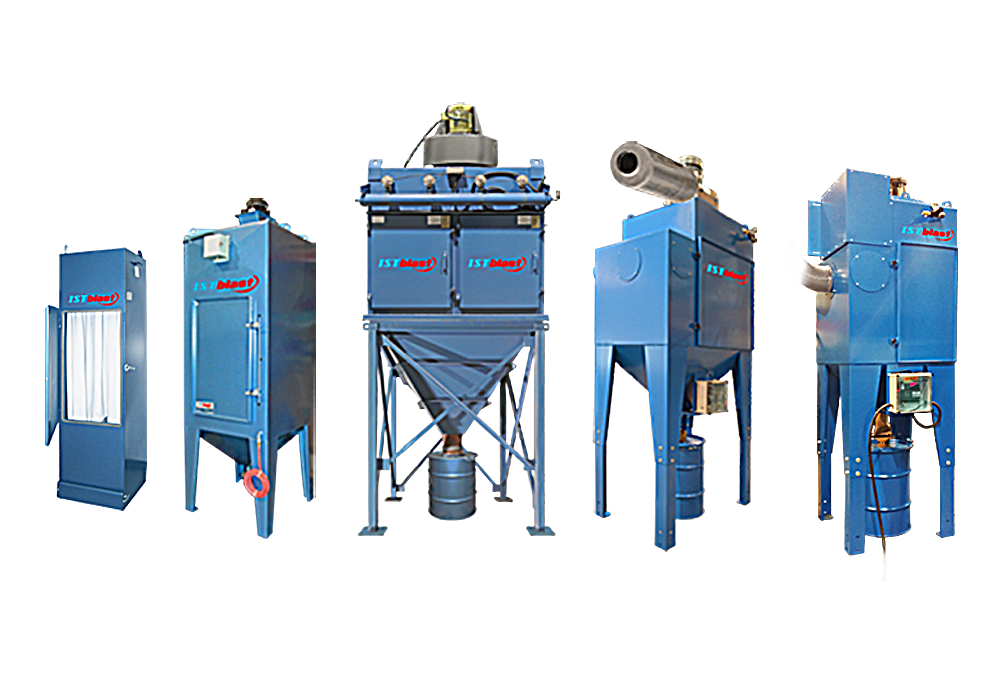

Some Known Details About Sandblasting Machine

Table of ContentsSandblasting And Painting Near Me - TruthsThe Ultimate Guide To Sandblasting And Painting Near MeSandblasting for BeginnersThe Ultimate Guide To Sandblasting AluminumThe Greatest Guide To Sandblasting At Home

Mobile applications may or may not recycle the abrasive. A blast closet is basically a closed loop system that permits the driver to blast the part and recycle the unpleasant. It generally includes 4 elements; the containment (cabinet), the abrasive blowing up system, the rough recycling system as well as the dust collection.Automated blast cabinets are likewise used to refine big quantities of the exact same element and might integrate multiple blast nozzles and also a part transportation system. There are three systems typically made use of in a blast cabinet. 2, siphon as well as pressure, are dry and one is damp: A siphon blast system (suction blast system) utilizes the compressed air to create vacuum cleaner in a chamber (recognized as the blast weapon).

The rough mix takes a trip with a nozzle that directs the fragments toward the surface area or workpiece. Silicon carbide and also boron carbide nozzles are much more put on immune and also are often made use of with more difficult abrasives such as aluminium oxide.

Unknown Facts About Sandblasting

Each application may call for using various pieces of tools, nevertheless, there are numerous key elements that can be located in a normal blast area: An unit or control system, generally the area itself, developed to stay sealed to avoid blast media from leaving A blasting system; wheel blasting as well as air blasting systems are frequently used A blast pot a pressurized container full of abrasive blasting media A dust collection system which filterings system the air in the space and also prevents particulate issue from escaping A material recycling or media reclamation system to accumulate rough blasting media so it can be made use of again; these can be automated mechanical or pneumatically-driven systems set up in the flooring of the blast area, or the blast media can be gathered manually by sweeping or shovelling the material back right into the blast pot Additional devices can be included for comfort and enhanced functionality, such as overhanging cranes for manoeuvring the work surface, wall-mounted systems with multiple axes that permit the driver to reach all sides of the work surface, and sound-dampening products utilized to minimize noise degrees.

Mineral: Silica sand can be utilized as a sort of mineral abrasive. It has a tendency to separate quickly, developing large quantities of dirt, subjecting the driver to the possible growth of silicosis, a debilitating lung disease. To counter this risk, silica sand for blasting is commonly coated with materials to regulate the dirt.

Some Known Factual Statements About Sandblasting Alternatives

Silica is a typical abrasive in countries where it is not banned. An additional common mineral abrasive is garnet. Garnet is a lot more expensive than silica sand, yet if utilized appropriately, will certainly provide equal production prices while creating less dirt as well as no security hazards from ingesting the dirt. Magnesium sulphate, or kieserite, is often utilized as an alternative to cooking soda.

Several consumers are eager to pay extra for jeans that have the appearance of being used. To offer the fabrics the best used appearance sandblasting is utilized. Sandblasting has the risk of triggering silicosis to the workers, and also in Turkey, greater than 5,000 workers in the fabric sector deal with silicosis, as well as 46 individuals are recognized to have died from it.

7 Simple Techniques For Sandblasting Machine

like it A 2015 research study verified that silicosis is practically inevitable among previous sandblasters. Sweden's Fair Trade Facility performed a survey amongst 17 fabric firms that revealed extremely couple of understood the risks triggered by manually sandblasting jeans. Numerous business said they would certainly eliminate this strategy from their own production. In 2013, study claimed that in China some manufacturing facilities creating worn-look jeans are entailed in varied non-compliance with wellness and also safety policies.Stucco Child uses sand blasting or poly prep solutions as essential actions on re-stuccoing your home. The existing problem of your stucco walls are the figuring out element of what process is best for you. Both procedures come with a lifetime service warranty as well as produce a structurally audio substrate for the leading layer to follow. sandblasting aluminum.

Sandblasting is also recognized as abrasive blowing up. Basically, it is the operation of by force moving a stream of rough material against a surface area. The sandblasting operation is done under high stress to smooth a rough surface area, roughen a smooth/Shape the surface area to eliminate its pollutants. There are numerous versions of sandblasting process like bead blasting, Soft drink blasting and fired blasting.

How Sandblasting Air Compressor can Save You Time, Stress, and Money.

If your task profile is related to sandblasting or you owned Read Full Article a company that included in the very same procedure, you need to stay with us. In this article, we will discuss sand blowing up makers materials and its pros and also corns. Before it, allow me additionally remove some of the details of its operation.- This process is best fit for metal surface areas, to stop moisture accumulation as well as prevent water intrusion in the surface area. Sandblasting is the process of thrusting rough by making use of the pressurized liquid or compressed gas as propellant. There are many common terms for this process that is generally associated with the sandblasting rough media used for this procedure.

Report this wiki page